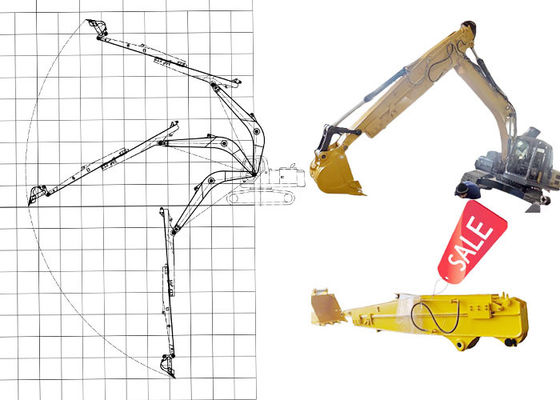

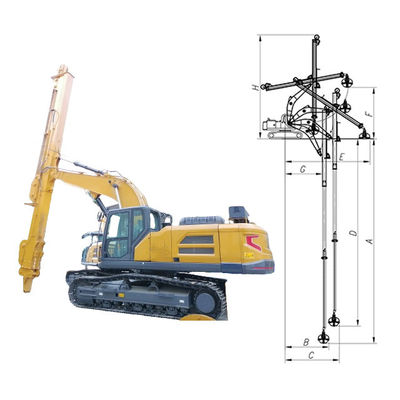

Μεγάλο Δαπέδιο Διπλής Όψης Φρέζα και Τρυπάνι:

Βελτιωμένη Ακρίβεια και Συνέπεια: Αυτό το φρέζα και τρυπάνι διπλής όψης βελτιώνει σημαντικά την ακρίβεια και την ομοιομορφία των εργασιών μηχανικής κατεργασίας, παρέχοντας αξιόπιστα αποτελέσματα.

Επεξεργασία μετά τη συγκόλληση: Μετά τη διαδικασία συγκόλλησης, το μηχάνημα πραγματοποιεί ολοκληρωμένο τρύπημα για να εξασφαλίσει την παραλληλότητα και την κάθετη των οπών του άξονα.

Βασικές Εφαρμογές: Χρησιμοποιείται κυρίως για τρύπημα μετά τη συγκόλληση του βραχίονα, του μικρού βραχίονα και του κάδου, εξασφαλίζοντας ακριβή ευθυγράμμιση και εφαρμογή.

Συγχρονισμένο τρύπημα και στις δύο πλευρές: Το τρυπάνι είναι ικανό να τρυπά και στις δύο πλευρές ταυτόχρονα, γεγονός που εγγυάται ομοιόμορφη ακρίβεια και συνέπεια και στις δύο επιφάνειες.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Σχετικά με την Kaiping Zhonghe Machinery Προφίλ Εταιρείας:

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Πιστοποιήσεις CE & Πιστοποιητικά Διπλωμάτων Ευρεσιτεχνίας της Kaiping Zhonghe Machinery

Τα προϊόντα μας έχουν εξαχθεί σε περισσότερες από 60 χώρες, χρησιμοποιώντας μια σειρά μεθόδων μεταφοράς, συμπεριλαμβανομένων θαλάσσιων, χερσαίων και εναέριων εμπορευματικών μεταφορών. Για τη συσκευασία, χρησιμοποιούμε ξύλινα κιβώτια ή μεμβράνη συρρίκνωσης για την προστασία των αντικειμένων. Πριν από την αποστολή, τα εμπορεύματα συσκευάζονται σχολαστικά και φορτώνονται σε εμπορευματοκιβώτια για να διασφαλιστεί η ασφάλειά τους καθ' όλη τη διάρκεια του ταξιδιού.

Κύρια προϊόντα: μακριά βραχίονα εκσκαφέα, βραχίονες κατεδάφισης, τηλεσκοπικοί βραχίονες 2-3 τμημάτων, βραχίονες σήραγγας, τυπικοί/βραχώδεις κάδοι, αρπάγες, εκσκαφείς, κ.λπ. Ελπίζουμε να έχουμε την ευκαιρία να κάνουμε μια προσφορά για την αναφορά σας.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Εικόνες Συσκευασίας & Αποστολής της Kaiping Zhonghe Machinery

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Συχνές Ερωτήσεις (FAQ):

Ε: Είστε κατασκευαστής;

A: Ναι, είμαστε κατασκευαστής και προμηθευτής βραχιόνων και εξαρτημάτων εκσκαφέων. Το εργοστάσιό μας είναι εξαιρετικά μεγάλο, ξεπερνώντας σημαντικά το μέγεθος των εγκαταστάσεων των ανταγωνιστών μας και είναι το μεγαλύτερο εργοστάσιο εξαρτημάτων εκσκαφέων στην επαρχία Γκουανγκντόνγκ. Διαθέτουμε ολοκληρωμένο εξοπλισμό παραγωγής και τα προϊόντα μας έχουν εξαχθεί σε περισσότερες από 60 χώρες παγκοσμίως.

Ε: Τι διακρίνει έναν κάδο κελύφους από έναν κάδο αρπαγής σε έναν τηλεσκοπικό βραχίονα;

A: Οι κάδοι κελύφους είναι συνήθως πιο αποτελεσματικοί για το χειρισμό ιλύος και άμμου, επιτρέποντας την εκσκαφή μεγαλύτερων όγκων γρήγορα. Ωστόσο, δεν διαθέτουν επαρκή δύναμη εκσκαφής για γενικές εργασίες άμμου και πέτρας και περιορίζονται από το μέγεθος του ανοίγματός τους, το οποίο μπορεί να μειώσει την απόδοση. Αντίθετα, οι κάδοι αρπαγής είναι πιο κατάλληλοι για τέτοιες εργασίες. Παρόλο που οι κάδοι αρπαγής τείνουν να είναι μικρότεροι και βαρύτεροι, τα πλεονεκτήματά τους γίνονται εμφανή όταν αντιμετωπίζουμε πιο σημαντικά υλικά όπως πέτρες.

Ε: Είναι προτιμότερο ένας μονός κύλινδρος ή ένας διπλός κύλινδρος για έναν κάδο κελύφους σε έναν τηλεσκοπικό βραχίονα;

A: Χρησιμοποιούμε σταθερά ένα σχέδιο διπλού κυλίνδρου, καθώς προσφέρει χαμηλότερα ποσοστά αστοχίας, ευκολότερη συντήρηση και μειωμένη διαρροή λαδιού. Ενώ οι κάδοι κελύφους διπλού κυλίνδρου είναι βαρύτεροι και μπορεί να έχουν ελαφρώς λιγότερο συγχρονισμό, οι κάδοι μονών κυλίνδρων είναι ελαφρύτεροι και παρέχουν καλύτερο συγχρονισμό και απόδοση αρπαγής, αν και με υψηλότερο ποσοστό αστοχίας.

Ε: Τι υλικά χρησιμοποιούνται για τον τηλεσκοπικό βραχίονα;

A: Ο σωλήνας του βραχίονα είναι κατασκευασμένος από BS900E, ενώ άλλα εξαρτήματα είναι κατασκευασμένα από Q355B, καθιστώντας τα ελαφρύτερα και πιο ανθεκτικά. Χρησιμοποιούμε πάχος 6mm για ενισχυμένη αντοχή.

Στοιχεία Επικοινωνίας:

Η Kaiping Zhonghe Machinery είναι ένας μεγάλος Κατασκευαστής Βραχιόνων και Βραχιόνων Εκσκαφέων

Λέξεις-κλειδιά: μακρύς βραχίονας εκσκαφέα, βραχίονας σωρού, βραχίονας κατεδάφισης, βραχίονας/σήραγγας, βραχίονας βράχου, τηλεσκοπικός βραχίονας κ.λπ.

Καλώς ήρθατε να επικοινωνήσετε για μια μεγάλη έκπτωση!

Whatsapp: +86 13822325403

Email: aria@excavatorboomarm.com

13822325403@163.com

Σύνδεσμος ιστότοπου: www.excavatorlongarm.com

κατασκευαστής excavatorlongarm longreachboomexcavator εκσκαφή excavatorshortenarm excavatorshortenboom σήραγγα tunnelarm tunnelboom

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!